1、机器人焊接工装夹具前后工序的定位须一致。

1, robot welding fixture before and after the process of positioning must be consistent.

2、由于变位机的变位角度较大,机器人焊接工装夹具尽量避免使用活动手动插销。

2, due to a variable angle positioner, welding fixture to avoid the use of manual bolt robot activities.

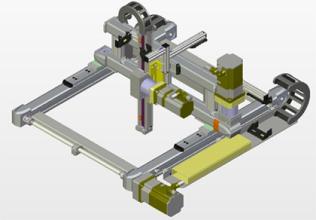

3、机器人焊接工装夹具应尽量采用快速压紧件,且需配置带孔平台。以便将压紧快速装夹压紧。

3, robot welding fixture should be used as soon as possible, and need to be equipped with a hole platform. In order to compress the clamping.

4、对零件的定位精度要求更高,焊缝相对位置精度较高,应≤1mm。

4, on the part of the positioning accuracy is higher, the relative position of the weld of high precision, should be less than 1mm.

山东自动焊接设备

5、由于焊件一般由多个简单零件组焊而成,而这些零件的装配和定位焊,在焊接工装夹具上是按顺序进行的,因此,它们的定位和夹紧是一个个单独进行的。

5, because the welding consists of several simple parts welded together, and the assembly and positioning of the parts in the welding, the welding fixture is in order, therefore, their positioning and clamping is a separately.

6、与普通焊接夹具不同,机器人焊接工装夹具除正面可以施焊外,其侧面也能够对工件进行焊接,可以无限延伸。

6, different from ordinary welding fixture, robot welding fixture in addition to the front can be welding, the side can also work on the welding, can be infinitely extended.

泰安扬帆数控科技有限公司(咨询电话 0538-5358300)座落在风景秀丽的泰山脚下,东平湖畔东临泰山,西依黄河,南与孔孟故里相望。京沪高铁、济广高速公路贯穿而过,交通非常便利。

泰安扬帆数控科技有限公司(13345281377)主要产品有焊接自动化成套装备、数控切割机、工业焊接机器人和数字化逆变焊接电源、焊缝跟踪系统及焊接摆动器等,是一家综合技术实力领先的自动化、智能化焊接成套装备的供应商。产品广泛应用于国内外机械制造、化工、汽车配件制造、农用机械、建筑、金属波纹管、太阳能热水器、电热水器、不锈钢制品等多个领域,在全国各个地区,产品质量和性能都受到了用户的一致好评。

诺商基于多年的优化经验和品牌基础推出的诺商商道系统,诺商信息您身边的互联网专家! |